As computing systems evolve to meet the growing complexity of real-time data processing, edge computing, and embedded communications, enclosure technologies must keep pace. One solution rising to the forefront is Lightweight Modular Scalability Chassis Engineering with Extruded Aluminium Profile — a practical, efficient, and reliable design choice for a wide array of computing and communication systems.

These enclosures are more than just protective shells. They serve as the backbone for robust, heavy-duty, and resilient computing platforms. Whether integrated into communication networks, telecommunication systems, or messaging systems, these chassis offer the scalability and endurance that high-performance applications demand.

Aluminium profiles bring unique advantages to chassis design. Their lightweight nature significantly reduces the system’s overall mass without sacrificing structural integrity. In addition, extruded aluminium provides excellent thermal conductivity, making it ideal for fanless or passively cooled applications. The profiles can be precisely machined and assembled into modular frameworks, allowing engineers to create, customize, and expand enclosures according to evolving system requirements.

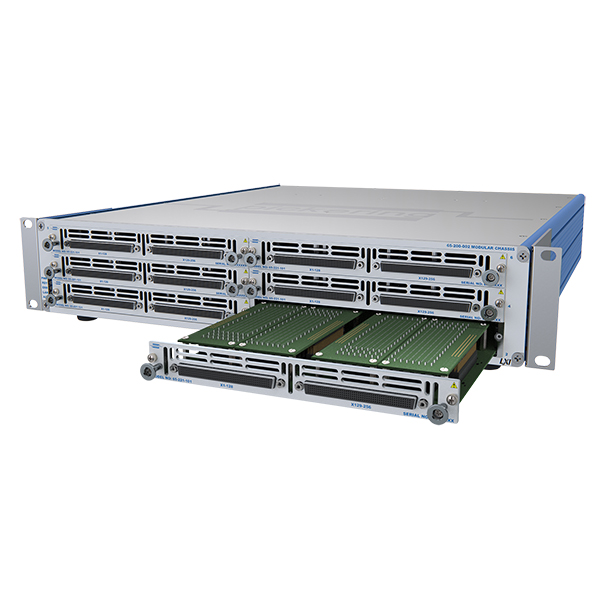

Modularity in chassis design enables flexible configurations. From 1U to 4U sizes and beyond, internal card guides, mounting rails, and ventilation schemes can be easily adapted, reducing engineering overhead when transitioning from prototype to full production.

This type of chassis engineering is widely adopted across sectors where performance and durability are critical. In the computer industry, such enclosures are favored for embedded servers, edge processing units, and AI-powered gateway devices. In the field of aerospace and defense, lightweight and shockproof builds are essential for mobile command centers and transportable computing nodes.

Additionally, these modular aluminium chassis are commonly found in the backbone of telecommunication infrastructures, housing networking modules, processors, and encryption systems that require secure and weather-resistant operation even in harsh environments.

Despite their advantages, the engineering and fabrication of modular aluminium chassis present several challenges. One of the primary concerns is maintaining mechanical precision during manufacturing. As the frame relies on tight tolerances for alignment and thermal contact, even small deviations during the fabrication process can affect performance or assembly ease.

Cable routing and component layout also pose difficulties. With scalable enclosures, internal configurations may vary widely, requiring designers to anticipate airflow, interference zones, and heat buildup for multiple scenarios. Efficient cabling becomes a critical part of the design, especially when dealing with high-speed communication modules or compact high-density I/O arrays.