Bespoke IoT Integration Aluminium Enclosure Design Optimization for EMI/RFI Shielding

The rapid growth of the Internet of Things (IoT) has revolutionized industries, from smart manufacturing to healthcare, but it also introduces a critical challenge: ensuring reliable performance in electromagnetically noisy environments. Bespoke IoT integration aluminium enclosure design optimization for EMI/RFI shielding addresses this need by combining advanced material science, custom engineering, and compliance-driven design to protect sensitive electronics from interference. This article explores the key strategies and innovations shaping this niche yet vital field.

The Role of Aluminium in EMI/RFI Shielding

Aluminium is the material of choice for IoT enclosures due to its unique properties. It is lightweight, corrosion-resistant, and offers excellent conductivity, making it ideal for EMI/RFI shielding. Unlike steel, aluminium’s natural oxide layer provides inherent corrosion protection, while its malleability allows for intricate, bespoke designs tailored to IoT device geometries. Advanced techniques like die-casting, extrusion, and CNC machining enable precise fabrication of enclosures with seamless joints, minimizing gaps where electromagnetic waves could penetrate.

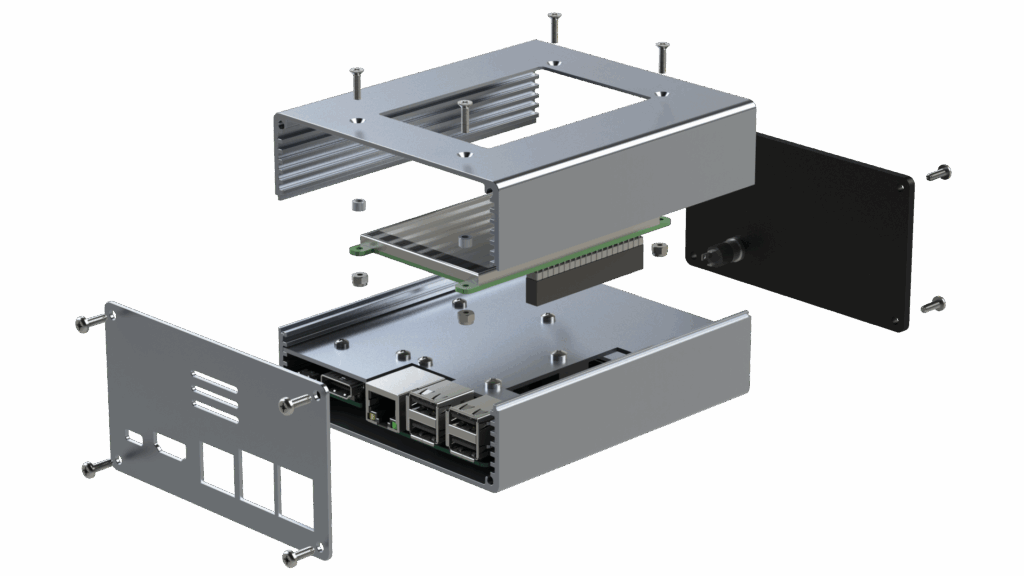

Design Optimization for IoT Integration

Bespoke IoT integration demands enclosures that balance form, function, and compliance. Key design considerations include:

- Shielding Effectiveness (SE): Achieving 60–100 dB attenuation requires multi-layered approaches, such as conductive gaskets, finger stock shielding, and honeycomb ventilation filters.

- Thermal Management: Aluminium’s high thermal conductivity pairs with integrated heat sinks or passive cooling channels to dissipate heat without compromising shielding.

- Modularity: IoT devices often require frequent upgrades. Optimized designs incorporate tool-less access panels and standardized mounting points for sensors, antennas, and PCBs.

- Aesthetic and Functional Customization: Laser etching, custom powder coatings, and IP-rated seals ensure enclosures meet both technical and branding requirements.

EMI/RFI Mitigation Strategies

To meet standards like IEC 61000-4-3 (EMC) and FCC Part 15, engineers employ several tactics:

- Conductive Coatings: Electroless nickel or zinc-arc spraying enhances surface conductivity.

- Gasket Integration: Silicone-or copper-filled gaskets seal joints and apertures.

- Board-Level Shielding: Pairing enclosure shielding with localized PCB shields creates a “double defense” against interference.

- Filtered Connectors: EMI-filtered cable glands and connectors prevent noise ingress through I/O ports.

Case Study: Smart Industrial Sensors

A recent project involved designing a bespoke aluminium enclosure for IoT sensors in an automotive assembly plant. The device faced intense EMI from robotic welders and RFI from wireless networks. By optimizing the enclosure with a multi-chamber layout, shielded cable ducts, and a conductive elastomer gasket, the design achieved 85 dB shielding at 1 GHz. Additionally, anodized finishes ensured durability in humid conditions, while modular panels allowed easy maintenance.

Future Trends

The next frontier in aluminium enclosure design optimization lies in smart enclosures with embedded IoT sensors. These “self-monitoring” enclosures could detect shield integrity, temperature fluctuations, or tampering, transmitting data to predictive maintenance systems. Additive manufacturing (3D printing) also promises faster prototyping of complex geometries with built-in shielding features.

Conclusion

Bespoke IoT integration aluminium enclosure design optimization for EMI/RFI shielding is not just a technical requirement—it’s a competitive advantage in today’s connected world. By leveraging aluminium’s versatility and cutting-edge engineering, businesses can future-proof their IoT deployments against electromagnetic challenges while maintaining scalability and aesthetics. As IoT permeates high-risk sectors like aerospace and medical devices, the demand for precision-shielded, custom enclosures will only intensify, driving innovation at the intersection of materials science and digital connectivity.